Behind every skin there is a long production process, made up of technique and talent.

Working leather responsibly does not just mean respecting certain rules, tanning is a long and complex process where each phase requires the utmost attention and each step is regulated by strict laws.

Our raw material is stocked in the raw hide warehouse.

The skins can be: fresh, fresh salted or in brine; the main way of preservation is by salting.

Inside rotating de-salting drums the hides are tumbled in order to remove the salt.

This process lasts for 48 hours and is divided into 3 sub-stages: wet-backing to rehydrate the hides, liming and then hair removal. At the end of this process the skins are referred to as “in lime”.

This is a mechanical process done by a machine called a fleshing machine that removes excess flesh and fat.

The material obtained is then processed to make useful products in the food, cosmetic and agricultural industries.

The material obtained is then processed to make useful products in the food, cosmetic and agricultural industries.

Tanning

The skins are delimed to remove previously used chemicals (especially lime). By means of pickling, the hides are treated in a saline solution to facilitate the penetration of the next step in the tanning process: chrome.

Chrome tanning is the most widely used and transforms the skins into Wet Blue, recognizable from its distinctive blue colour. This process may vary from 24 to 48 hours depending on the origin and type of the raw material.

The skins pass through a machine called the press/sammying machine which has special felt rollers that remove excess water and stretch the skin to facilitate splitting.

Splitting, as well as in lime, can also be performed on Wet Blue separating the grain (top) from the split (bottom) into the required thickness.

Skins are inspected and checked by experienced operators who, according to the characteristics of the articles, allot them into various selections.

After the skins have been selected, and once the type of article to be produced is specified, the hides are machine shaved to adjust and regulate the thickness. The waste from this process is made use of again by industries to extract various kinds of fertilizers.

DYEING

There are three stages to this process, all of which are carried out in the drum: Ritannage, to regulate the levels of chrome; dying, to define the color; fattening, to give the qualitative features to the article, in particular texture and softness.

The skin is stretched and fastened by means of metal clamps (toggles) on a special frame, slid through a large tunnel for about 2-3 hours, hot air is blown at 50/60° C which allows for a reduction in humidity.

Once dried, skins are trimmed to regulate the shape. At this point they are termed ‘semi-finished or crust’.

The skins pass through the staker: a machine made up of vibrating cylinders that softens and distends the hide and makes it more supple.

To obtain certain articles, some natural skin characteristics have to be corrected, by means of stuccoing.

Once the stucco dries, the hides are buffed. This is a process where the hides pass under a sanding roller and the surface is sanded (a process very similar to sanding wood). The residues from this process are collected for further use in fertilizers for agriculture. Full grain leathers are neither stuccoed nor buffed.

When the skins are semi-finished, further inspection and controlling is carried out by qualified operators.

PREPARATION AREA FOR FINISHING

According to each article specifications, the recipe for colour, shine and aesthetic feature is formulated and the mixture is prepared in the colour kitchen.

The mixture is gun sprayed and distributed uniformly on the whole surface of the skin.

For some articles, an emboss is imprinted on the surface using a roller or plate.

The milling drums give the softness to the article. The drumming time depends on the characteristics required.

The hides are ironed by means of a hot roller, which relaxes and stretches the skin, and helps achieve a smoother hand and regulate the degree of shine.

When the leather is finished it is inspected and scrupulously checked for all its technical and aesthetic features.

MEASUREMENT

Once the hides have been approved, they are measured and stamped with: size of area, logo, measurement date, and ID number for the company’s internal traceability records.

Real leather is real sustainability.

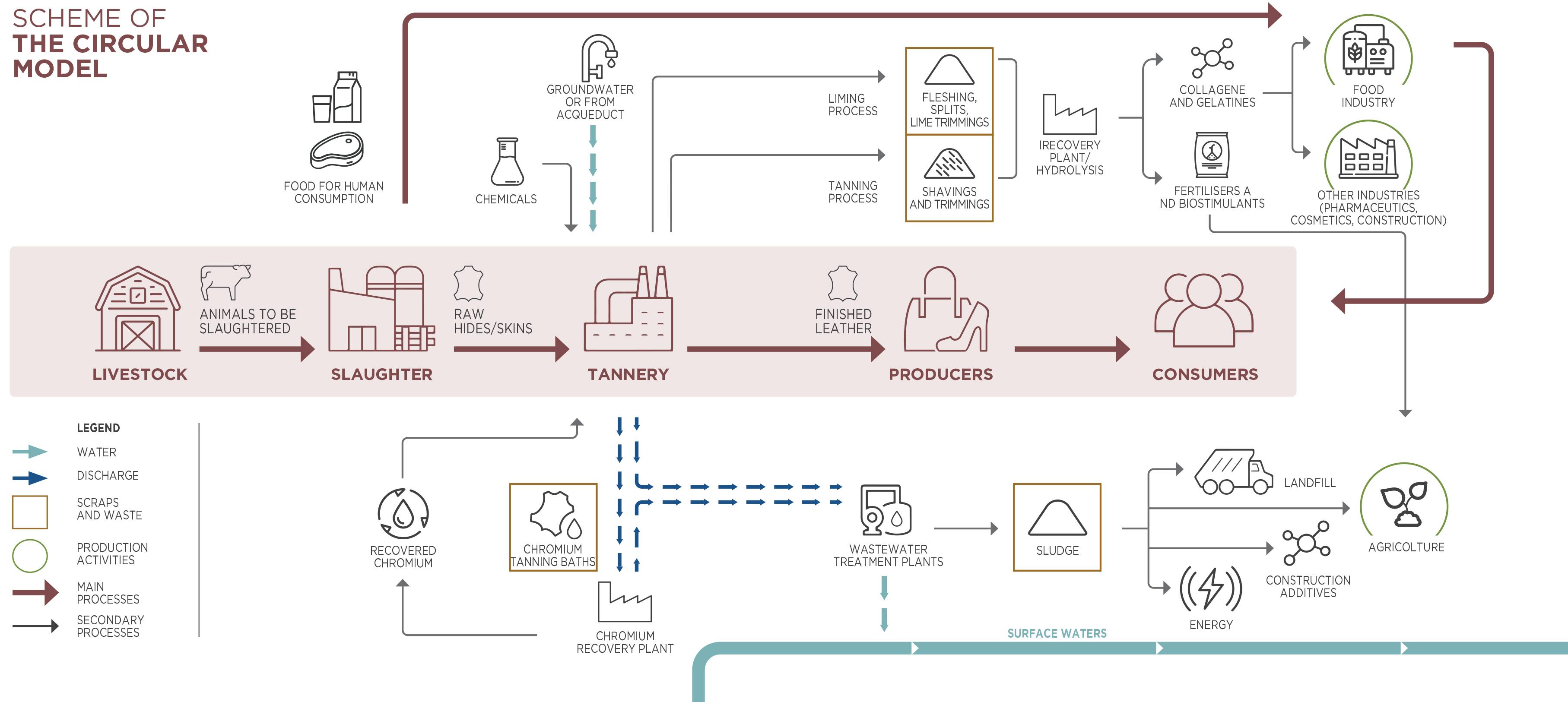

Look at the Circular Model of leather production and find out how waste is reused by other industries.